Pilot Coating Systems

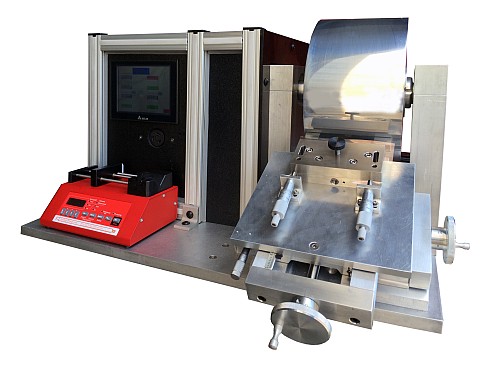

One of BSC’s specialties is in creating small scale pilot equipment that can simulate a full production process at a lower cost and enable an operation to verify the feasibility of an envisioned process. One example is a slot die loop coater that would enable you to test a new coating process and materials on a small economical scale that could also produce prototypes of new coated products.

Standard and Custom Dies

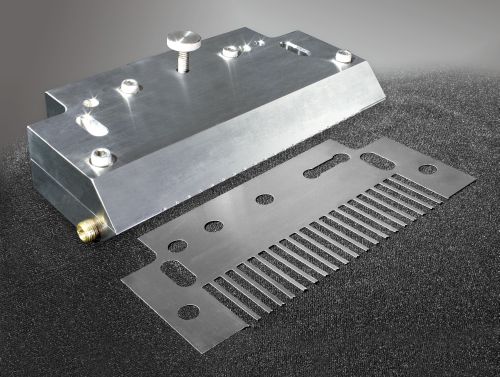

BSR slot dies offer a number of important advantages over others commercially available. The body, consists of two precision ground, stainless steel halves with one consisting of the reservoir. Various shim thicknesses can be selected to determine the ‘lip’ or slot opening width depending on liquid viscosity, feed rate and ultimately, coating thickness. BSC has been at the forefront in coating technology having implemented the first commercially viable coating technique for organic photovoltaics. Additionally, BSC provided a solution for coating of automotive headlights which resulted in a 50% increase in light output.

Custom Solutions

In most applications, other engineering firms had tried and failed. Our approach is unique. We create a dedicated team to take on the entire project. We work with the client to ensure that we understand all of the requirements – time, quality and cost.

Precision Metered

A benchtop coating apparatus, that requires very low fluid volume to coat onto a 15” long 4” wide strip of substrate. The standard model includes a 4” slot die with specially designed coating channels that require only 5-10ml of coating to fill the entire fluid path. Additional coating stations are available as customized add-ons. The EZCoater enables precise metered fluid delivery that was only available in large production coating equipment. The use of the EZCoater allows for the study or evaluation of coating fluids with minimal waist and clean up.